|

|

Soldering guide - How to solder

Safety precautions

- Keep flammable liquids and materials away from the work area.

- Soldering with lead may produce fumes that are hazardous. Flux containing rosin (colophony) produces solder fumes that, if inhaled, can be hazardous. Use smoke absorber - smoke absorber absorbs most of hazardous smokes from flux and solder.

- Solder only in a well ventilated area.

- Soldering iron is HOT. Never touch tip of the soldering iron.

- Never set your hot iron down on anything other than an iron stand.

- Wear eye protection.

- Never cut off a grounding prong on an iron plug to make it fit an ungrounded receptacle.

- Hold wires to be heated with tweezers, pliers or clamps to avoid receiving burns from objects that are heated.

- Always wash your hands with soap and water after soldering.

Preparation for soldering

|

Turn on your soldering iron. Set desired temperature on soldering iron . Dampen the sponge in the stand (sponge should be damp, not soaking wet). Turn on smoke absorber if you have one. |

|

Clean the soldering area and dirty components. All components must be clean and free from oxidation, grease, and other contamination. Solder will not stick to dirty component or dirty area on printed circuit board. |

|

Iron tip must be clean as well. Clean the iron bit using the damp sponge. |

|

Before soldering, the iron tip should be “tinned” or, in other words, coated with solder. Apply some solder to the iron tip, then wipe on the damp sponge. |

|

If you are soldering static sensitive components, wear anti-static protection (ESD) like a wrist strap (in this picture). |

Soldering

|

Insert component. |

|

Take soldering iron from stand and hold it as a pen. |

|

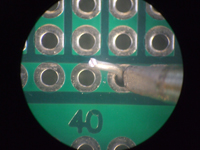

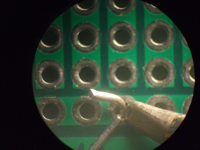

Apply a tip of soldering iron to the joint and hold for few seconds. Make sure it touches both the track on circuit board and the component lead. |

|

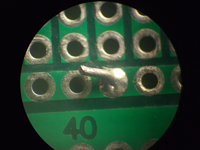

Continue heating and apply some solder to the joint, not the soldering iron. Heating one part but not the other will result in poorly formed joints. Solder should melt and flow smoothly onto the track and component lead to form volcano shape. The most common problems with soldering are adding too much or not enough solder. |

|

It only takes couple seconds to make a perfect joint. The heating period depends on the temperature of your iron and size of the joint.

First remove the solder, then remove the soldering iron while keeping the joint sill. Do not move circuit board for a few seconds to allow the joint to cool. |

|

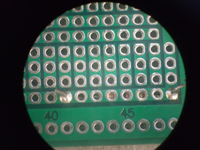

Inspect soldered joints. Adjacent components may be bridged together or the joint may need additional solder for good electrical continuity. |

Where to buy soldering iron in USA

|